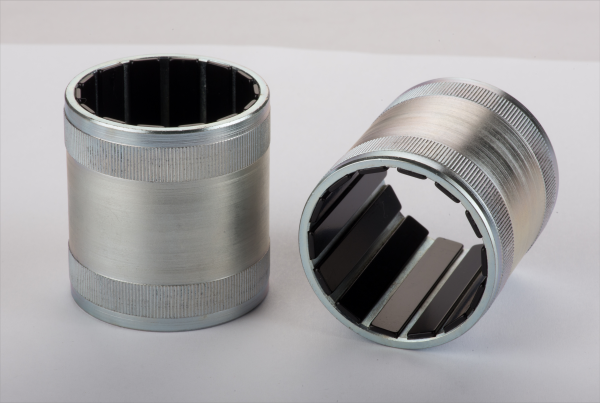

Magnetic Rotor

A magnetic rotor is a core component used in various devices, particularly in electric motors, generators, and alternators. Its primary function is to generate a magnetic field that interacts with the stator to produce mechanical motion or electrical power. Here's a detailed introduction to magnetic rotors:

1. Construction:

- Magnetic rotors are typically composed of a central shaft surrounded by a series of permanent magnets or electromagnets arranged in a specific configuration.

- The magnets are usually made from materials such as neodymium, samarium-cobalt, ferrite, or other high-strength magnetic materials to ensure a powerful and stable magnetic field.

- In some designs, the magnets may be mounted on the surface of the rotor or embedded within the rotor core, which is often made of materials like iron or steel to enhance magnetic flux density and structural integrity.

2. Functionality:

- In an electric motor, when the rotor is energized with an electrical current, it generates a magnetic field that interacts with the stator's magnetic field. This interaction produces a torque on the rotor, causing it to rotate.

- The rotation of the rotor shaft transfers mechanical energy to the connected load, such as a fan, pump, conveyor belt, or other machinery.

- In a generator or alternator, the rotor is either mechanically rotated or driven by an external power source. As the rotor rotates, it induces an electrical current in the stator windings through electromagnetic induction, producing electrical power.

3. Applications:

- Magnetic rotors are integral components in a wide range of electromechanical devices used in various industries.

- They are commonly found in electric motors used in industrial machinery, automotive applications, household appliances, robotics, HVAC systems, and more.

- In generators and alternators, magnetic rotors are employed in power generation systems such as wind turbines, hydroelectric generators, gas turbines, and diesel generators.

4. Advantages:

- Efficient energy conversion: Magnetic rotors facilitate the conversion of electrical energy into mechanical motion (in motors) or vice versa (in generators) with high efficiency.

- Compact and lightweight: They offer a high power-to-weight ratio, making them suitable for applications where space and weight considerations are crucial.

- Low maintenance: Permanent magnet rotors require minimal maintenance compared to rotors using electromagnets, which may need periodic inspections and maintenance of the winding insulation and cooling systems.

In summary, magnetic rotors are essential components in electromechanical systems, enabling the conversion of electrical energy into mechanical motion or electrical power. Their versatility, efficiency, and reliability make them indispensable in a wide range of applications across various industries.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Esme

Phone: +86-15906564908

E-mail: esme@super-magnets.com

Add: 403, Building 1, No. 818 Jinyuan Road, Yinzhou District, Ningbo,Zhejiang, China